Products: Fuel Filter Separators

Product Overview

Admiral's fuel filter separators provide efficient removal of free or entrained water and solids from engine fuels. Ideal for marine, land and aircraft fuel filtration applications, Admiral's fuel filter separators can be fabricated from:

- Carbon Steel

- Stainless Steel

- Monel

- Copper Nickel

- Aluminum

and meet or exceed the performance requirements of MIL-F-8901.

Applications

- Jet Fuels

- Fuel Oils

- Kerosene

- Gasoline

- Solvents

- Refineries

- Bulk Plants

- Airports

Features

- O-Ring for tight sealing of vessel.

- Swing bolt closure for easy access to coalescer and separator elements.

- Monitoring of inlet, differential and separator elements.

- Automatic discharge valve shuts down flow when a slug amount of water enters the vessel.

- Automatic drain valve opens to remove water after reaching a predetermined level.

- Sight glass allows visual verification of water level.

Process Description

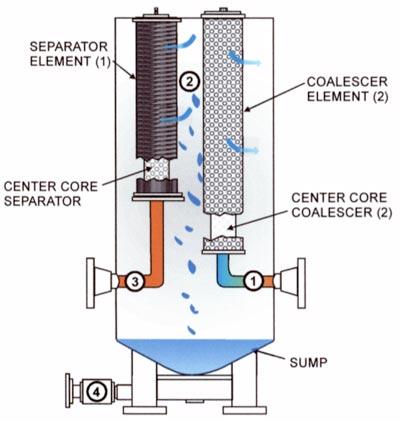

- Unprocessed fuel enters the filter separator through the inlet port and flows through an elbow and tee assembly upward into the bottom of the two coalescer elements

- Fuel flows through the coalescer elements from inside to outside filtering out solid contaminants and coalescing entrained water into large droplets that sink to the sump area. The fuel then passes through the separ ator element from outside to inside, and any remaining water is removed.

- After passing through the separator element, the clean fuel is discharged via a pipe and elbow and exits the filter separator through the outlet port.

- The float assembly senses the level of water in the sump and discharges it through the valve when the water reaches a predetermined level.

Specifications

|

Design Pressure* Operating Pressure* Test Flow Range* Maximum Pressure Drop* |

150 psi 75-150 psi 150% of design pressure 10-500 GPM 5 psi |

1034.3 kPa 517.1 - 1034.3 kPa

2.3 m3/hr - 115.6 m3/hr 34.5 kPa |