Products: Oily Water Separators

Designs

Admiral is unique in that it is not limited to offering only one design of oily water separator. Instead, Admiral offers three distinct designs, thereby ensuring the widest possible selection of product.

Sigma

- World's largest range

- Worldwide acceptance

- Ease of maintenance

- Proven reliability

- Excel in adverse conditions

Sigma

Proven on countless ships, commercial and naval, plus land-based installations, Sigma units are offered in the rangeof2 GPM (0.5 cu. m/hr.) upto 50 GPM (11.4cu. m/hr.) The system is designed for totally unmonitored operation on oils up to 0.94 sg. All units are certified to MECP60-33-1. The unit is essentially self cleaning and the small overall size is a definite asset. With low height, it has proven extremely effective under conditions of extreme sea states and heaters are provided for use in extreme cold. The unit is also qualified and available in explosion proof configurations.

Sigma 2 SeriesProduct OverviewPrimarily built for marine applications, Sigma units are in service worldwide with military and merchant vessels. Flexibility is the key, with the S2 Series processing capacity ranging from 2 GPM (0.5 cu. m/hr). up to 50 GPM (11.4cu. m/hr).The S2 Series will continuously process bilge waste unattended, discharging effluent overboard at less than 15 ppm (parts per million) oil in water. With an exceptionally small envelope, (at least 50% smaller than similar capacity units), and quick and easy installation, the S2 Series allows the extra area to be used for other components or systems. The control panel continuously monitors operation, clearly displaying the current processing mode. Sigma units are fitted with state-of-the-art Oil Content Monitors and meet all current US Coast Guard and IMO regulations. The Sigma S2 Series represents the latest in Oily Water Separation technology from Admiral, a world leader in complex filtration. |

S2-1T Model with a single separating tank. Single phase, 4 GPM unit fitted with a Shimadzu Oil Content Monitor. |

S2-50 Model with two separating tanks. Three phase, 50 GPM fitted with a Fellow Kogyo Oil Content Monitor. |

Features

- Effluent quality less than 15 PPM oil in water

- Tank Construction-Carbon Steel

- Pump-progressing cavity with 416 SS rotor

- All threaded pipes and fittings-bronze

- Tank safety valve-15 psi

.

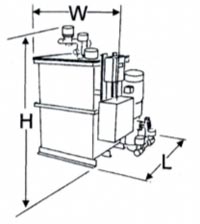

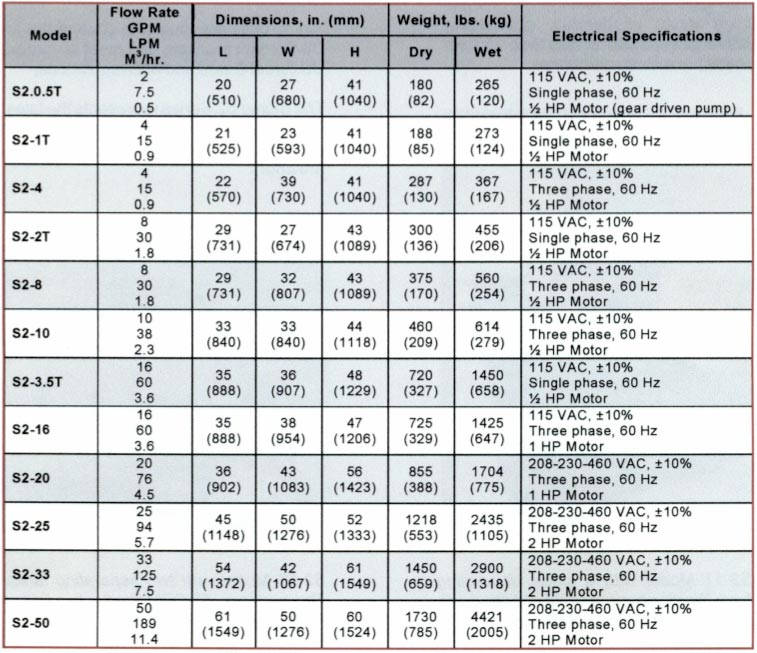

Model Listing

Sigma Process Description

.

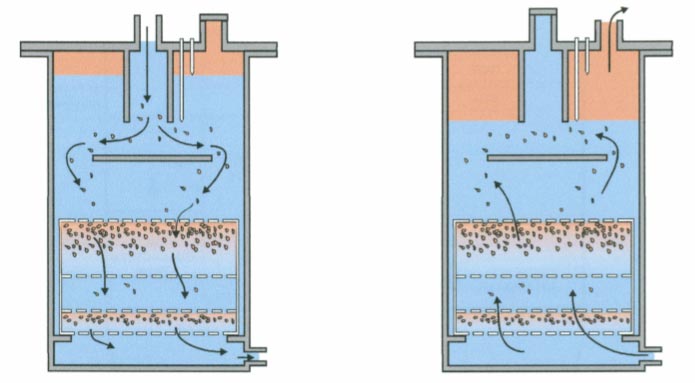

Processing Mode: Oily water is drawn from the bilge into the separator with suction provided by a positive displacement pump on the discharge side of the separator.

Several separation zones are created by the inlet weir and baffle, two coalescer beds, and quiescent water spaces in between them.

The upper zone of the tank assists in gravity separation. The inlet baffle diverts the flow away from the upper coalescer bed, enabling oil droplets to float to the tank top. The inlet weir divides the gross oil accumulated in the tank from the inlet flow.

The polypropylene beads contained in the coalescer beds attract oil and repel water (oleophylic-hydrophobic), allowing water to flow through while the oil remains attached to the surface of the beads. These oil droplets accumulate in the beds and grow in size, then become buoyant and float to the tank top. The clarified effluent exits through the outlet at the bottom of the tank and is discharged by the pump.

.

Oil Discharge Mode: When the lower level probe detects oil, the system enters the oil discharge mode. The pump stops and the automatic valves open to allow back–flush water into the bottom of the tank. The water back–flushes the coalescer beds while displacing the oil from the top of the tank to an oil containment tank.

Oil Content Meter/Bilge Alarms: The S2 series of Oily Water Separators are compatible with all approved oil content meters (15 ppm bilge alarms). Automatic re–circulation is included on all S2 units that are delivered with a bilge alarm. Remote alarms are available as an option.

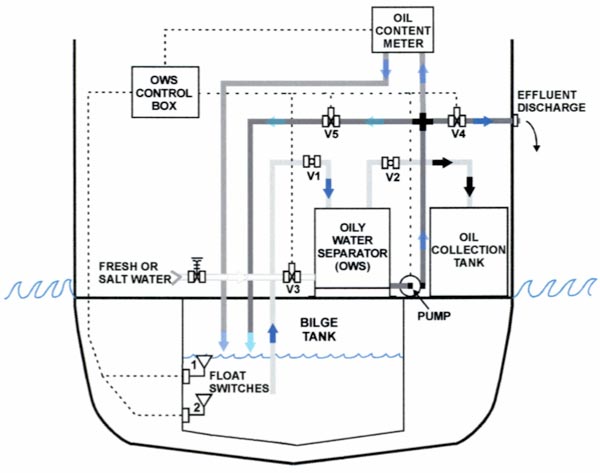

Sigma Typical System Application

- When float switch 1 is activated, V1 is opened and the PUITl> is switched on, bilge water is drawn into the top of the Oily Water Separator (OWS).

- A probe in the OWS (see Process Description) senses when the amount of separated oil has reached a predetermined limit, causing V2 and V3 to be opened.

- Opening V3 causes fresh or salt water to enter the OWS for back–flushing while also displacing the separated oil at the top of the OWS.

- V2 allows the discharge of the separated oil into the Oil Collection Tank.

-

An effluent sample is pumped to the Oil Content Meter to determine if the oil content is less than 15ppm.

- V4 is normally open and if the sample is less than 15 ppm, the processed effluent is discharged into the sea.

- If the sample is greater than 15 ppm, V4 is closed and V5 is opened and the cleaned water is returned to the Bilge Tank and then to the OWS for further cleaning.